FOAM PACKING & DISPENSING EQUIPMENT

Please view our instructional videos for everything you need to know about the EZ-Flow system.

The EZ-Flow Product Line

Check out our foam packaging equipment and the rest of the E-Z Flow Foam product line.

GHC-220 Heavy Duty System

![]() Our top of the line. The GHC-220 will handle any size of container or any volume of foam you want to dispense. This unit is the best fit for assembly line use and for really big applications. The GEN IV Controller allows accurate temperature control, internal diagnostics, and safety features for your peace of mind.

Our top of the line. The GHC-220 will handle any size of container or any volume of foam you want to dispense. This unit is the best fit for assembly line use and for really big applications. The GEN IV Controller allows accurate temperature control, internal diagnostics, and safety features for your peace of mind.

More Info and Specifications for the GHC-220 Heavy Duty System

GHC-110 Medium Duty System

![]() Our most popular unit. Perfect for most applications, the GHC-110 is robust and durable, reasonably priced, and easy to use. Built with many of the same heavy duty components as our GHC-220, but uses standard 110V wall power.

Our most popular unit. Perfect for most applications, the GHC-110 is robust and durable, reasonably priced, and easy to use. Built with many of the same heavy duty components as our GHC-220, but uses standard 110V wall power.

Now with our GEN IV technology for greater safety and ease of use.

More Info and Specifications for the GHC-110 Medium Duty System

Drum Pumps

We offer Stainless Steel pneumatic Drum Pumps from IPM, in either standard (for 55 gallon drums) or short lengths (for 15 gallon kits). Proven and reliable, with safety features exclusive to E-Z Flow, these pumps are designed to give years of trouble free operation.

Options

Several options are available for custom applications. These include:

- A Shot Timer for the Medium and Heavy Duty systems. With this option, you can program up to six different timed shots in succession. Ideal for repetitive operations such as filling molds.

- Custom cartridges: We can provide cartridges with different ratios, up to 3:1 A to B or B to A. We can also offer larger orifices for higher pour volumes or higher viscosity chemicals.

- Remote Dispensing Head: A modification of our standard Dispensing Gun, for use in robotic applications or other areas where remote dispensing is needed. Can be mounted on a variety of platforms.Please contact us for more details.

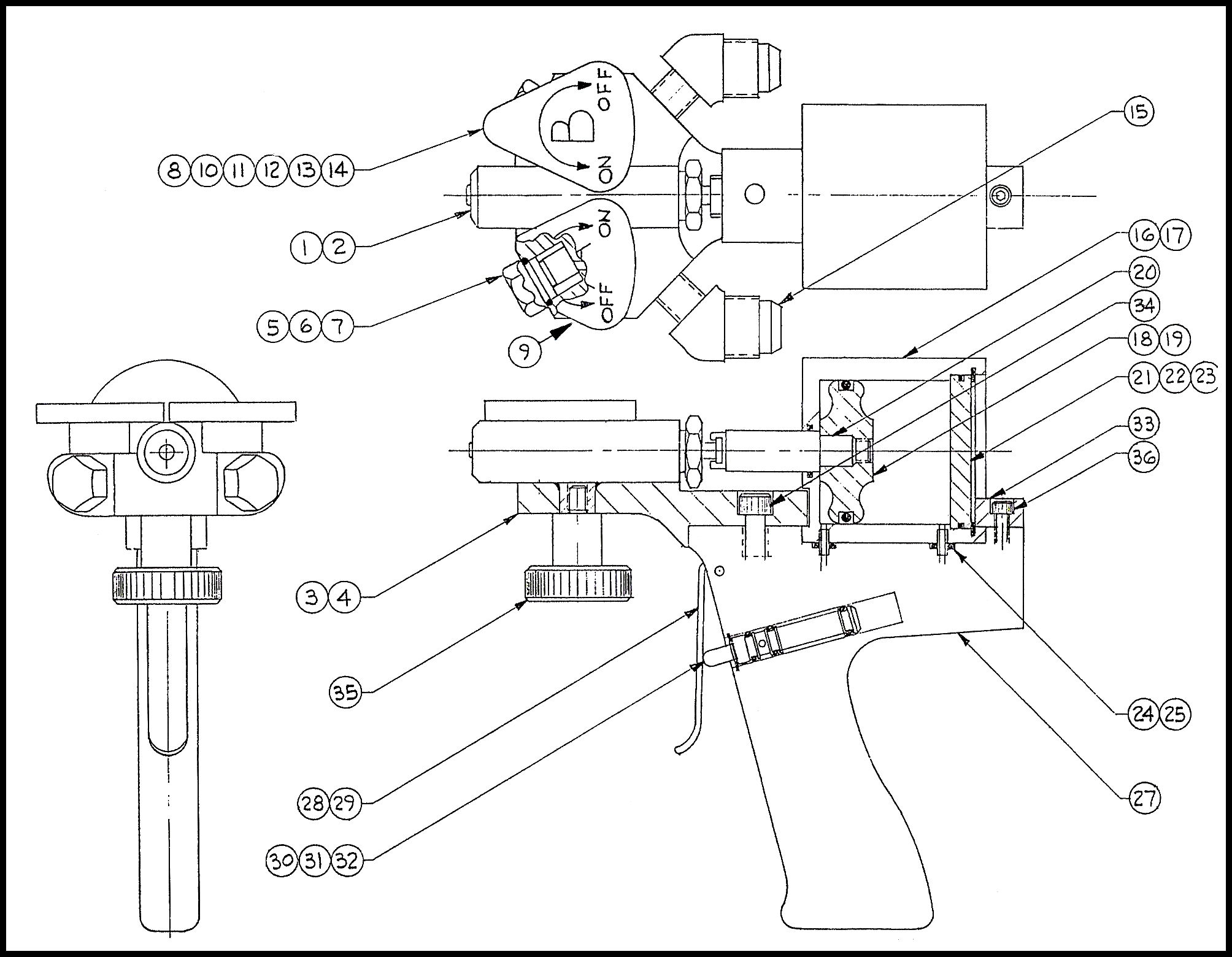

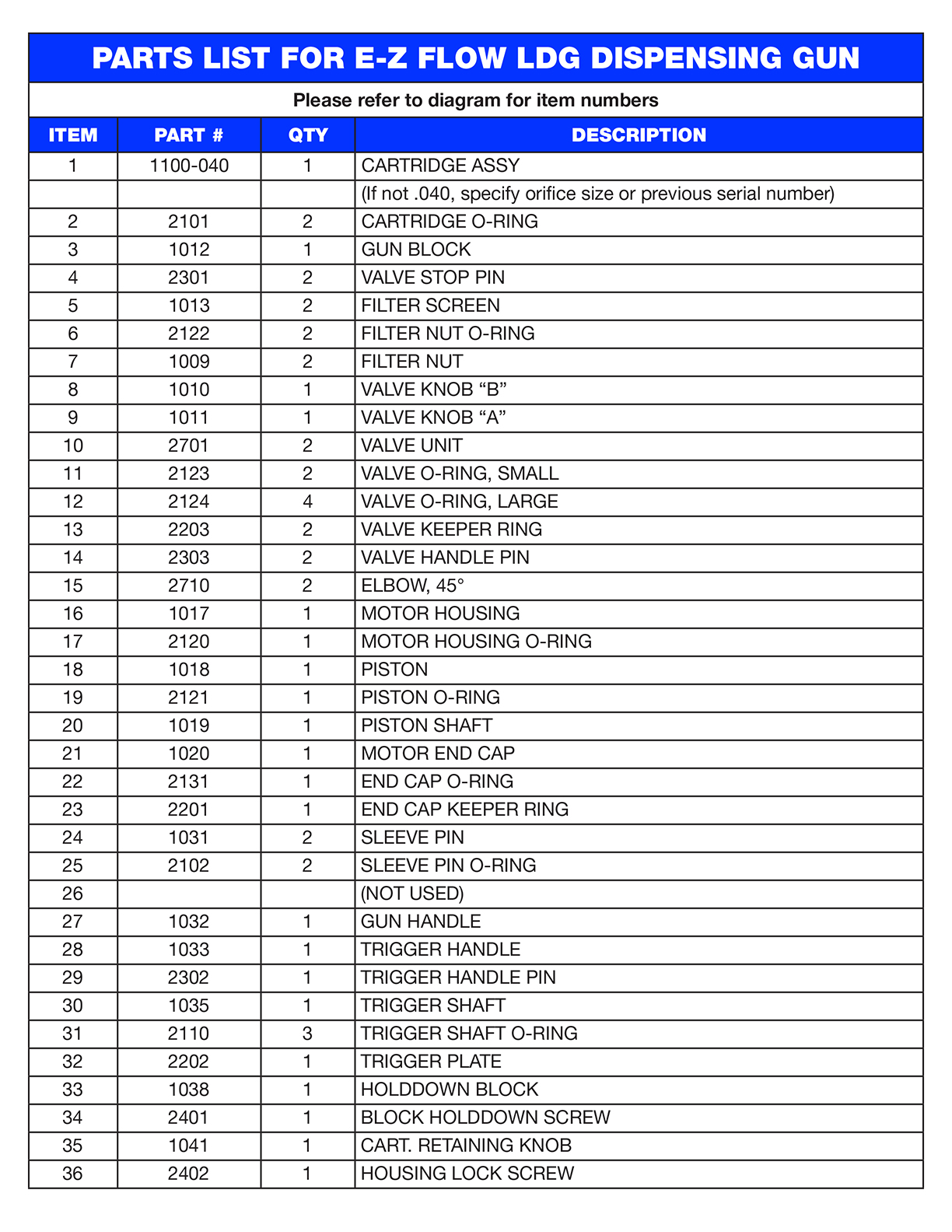

Here is a parts diagram for our Dispensing Gun

Please click on the photos of the gun, diagram or parts list for the a larger version.

What is Foam Packing and Dispensing Equipment?

Foam packing and dispensing equipment is designed to create and apply foam materials used for protective packaging and void filling in shipping and storage. This equipment automates the process of generating foam, ensuring consistent quality and efficiency in packaging operations.

The foam used in this context is typically polyurethane or polyethylene, which is valued for its cushioning properties and ability to absorb shocks and vibrations during transit. The equipment generally consists of a mixing unit where chemicals are combined to form the foam, a dispensing system that accurately delivers the foam into packaging, and sometimes a cutting or shaping mechanism to customize the foam’s form for specific applications.

Key types of foam packing and dispensing equipment include foam-in-place systems and foam-in-bag systems. Foam-in-place systems involve dispensing liquid foam directly into a box or package where it expands to fill voids and secure items. Foam-in-bag systems, on the other hand, inject foam into pre-made bags that are then placed around the product.

The benefits of using foam packing and dispensing equipment include enhanced protection for goods, reduced labor costs due to automation, and improved efficiency in packaging operations. This equipment is essential in industries where fragile or sensitive items need secure and reliable packaging, such as electronics, medical devices, and automotive parts.